Most people are familiar with layflat hose and their use in firefighting, but many people have yet to realise that they are also a great option for bore water pumping. Due to its flexible nature, layflat hose has many advantages over rigid pipe. It is compact and can be transported using a lighter vehicle. Layflat hose allows for rapid installation: it is easily deployed and retrieved by simply unwinding and rewinding. Layflat hose has excellent hydraulic performance due to its swelling and resistance to internal build-up of iron bacteria; it will always maintain perfect pumping efficiency.

Our Flexibore® is a world industry-standard flexible rising main with 300 m length options. With this capability, many ground water resources are able to be drawn down using this easy-to-install riser pipe. Flexibore® is set up and connected to the pump with stainless steel couplings providing a strong fix that can handle high water pressures and ultra-high pressures of up to 90 bar in the 400 series.

At Crusader Hose, we can offer solutions for your pumping requirements in a bore hose or a well hose with the Flexibore® flexible rising main. Where there is need for water to be extracted upwards for farming or for a water table to be lowered in mining, a flexible rising main is often the best choice.

Compact and easy to transport

In many fluid transfer applications involving high volumes, the use of layflat hose is able to overcome many limitations inherent to rigid pipe use. It has the ability to be deployed and retrieved quickly and the flexibility of the hose adapts to undulating terrain. Layflat hose by its very nature can be coiled up compactly and thereby has a small storage footprint that makes it easy to handle and transport.

Rigid pipes are cumbersome and bulky, requiring a lot more joints, welding, machinery and manpower to install and remove. Whenever you have the opportunity to convert from rigid pipes to flexible hose, you’ll never look back.

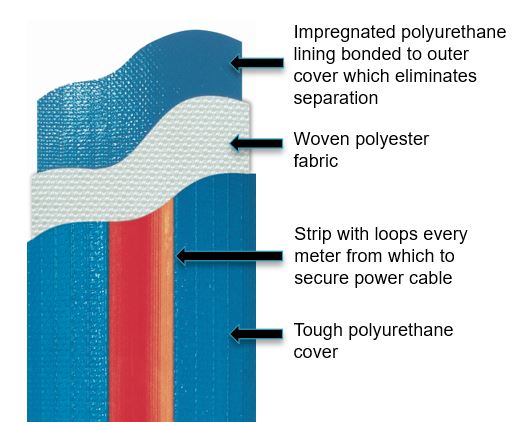

At Crusader Hose, we manufacture woven reinforced hose using high-tenacity polyester yarns. This weaving process allows the fabric to interlock and achieve a very high burst pressure and tensile strength (end pull) ratings. Thermoplastic polyurethane (TPU) is then pushed through the woven jacket using thru-the-weave extrusion to give a tough integrated cover for exceptional strength and hydraulic efficiency.

Never doubt the strength of the Flexibore® interlock weave technology. Don’t be confused by other layflat hose products with yarns that are braided or knitted, which are not suited to suspend heavy pumps.

Trust Flexibore® by Crusader Hose. Ask for it by name.

To learn more about the advantages of Flexibore® click here or for more information on all our layflat flexible pipe and hose solutions, click here or contact Crusader Hose on